Torque sensors and Torque transducers

Torque Measurement Solutions Available from Datum Electronics

Datum Electronics specialise in the design and manufacture of Rotary Torque Sensors and Rotary Torque Measurement solutions. The product range includes torque sensors from 1 Nm up to 500,000 Nm and installed shaft solutions for shafts from 5mm diameter up to 1100mm diameter as power and torque monitoring systems.

As well as our standard ranges of transducers we offer a wide range of specialist modular solutions that can be cost effecively engineering to meet your requirements. The RS420 and FF420 ranges can be engineered to replace existing couplings and drive shafts within your test rig or machinery minimising any mechanical changes required.

Torque Measurement

Torque Sensors

How to measure Torque

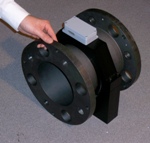

M420 Rotary Torque Sensor

|

Conventional torque transducer with rotary shaft and static body plus high accuracy and direct serial data output. This complete packaged torque sensor transmits the torque signal from the rotating shaft within the transducer body. The static element of the sensor is mounted to the rotary shaft with bearings. Ideal for applications that require the sensor to be mounted in line with the driven torque including test rig applications.

High Accuracy 0.1%

Proven Digital Data Transmission Technology

Robust and Reliable |

|

Flange mounted transducers with non-contact transmission to stator.

Standard DIN Flange range 100Nm to 100KNm

Modular Range fitted to Coupling Spacers 50Nm to 500KNm

Simple to mount, rotor stator air gap +/-3mm up to +/-10mm, no-bearings, direct serial data output with torque and shaft rpm, analogue output options 4-20mA or +/-10Vdc.

Load Ratings 50Nm to 500KNm

|

|

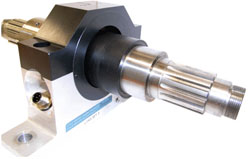

Shaft mounted transducer with non-contact transmission to stator. The rotary shaft can either be keyway or splined as standard, or be made to custom fit shafts as required. With no bearings the mass of the transducer added to the transmission line is greatly reduced when compared to a transducer with bearings. Ideal for applications that require low maintenance and long term operational requirements.

High Accuracy

Fitted to Free Issue Rig or Machinery Transmission Shaft

Low Rotor Mass

No Bearings |

FF410 Static Torque Transducer

|

The Datum Electronics Series 410 Static torque sensor was developed following developments of our FF420 series of rotary torque transducers. The same basic shaft components and strain gauge technology have been applied to our 410 Reaction transducer range providing a competitive option within the static transducer market. |

Marine Torsionmeter Systems

|

Datum Electronics Series 420 Marine Torsionmeter System provides an accurate tool to assess and monitor propeller shafts on ships by measuring shaft speed, torque and power. This Torsionmeter system can be installed on a ships propeller shaft or shafts and uses strain gauge technology providing a highly accurate non-contact method of measuring shaft torque. |

Shaft Power Meters

The Datum Electronics Series 420 Shaft Power Meter provides an accurate tool to access and monitor the performance and efficiency of the ships transmission system. The transducer accurately measures the on-shaft torque (kNm), speed of the shaft rotation (rpm) and the power (kW) that is going through the shaft. The system can be applied to both single and dual shaft ship systems.

Drive/Prop Shaft Torque

Whatever the application, an accurate and simple torque measurement of the transmission can be invaluable to improve designs, protect the machinery, reduce maintenance costs and control performance. The two PTO Drive Shaft Systems offered by Datum Electronics provide effective on-shaft torque monitoring which will fit a wide range of shafts and give effective measurement of power through the drive shaft.

PTO / Power Take Off

Datum Electronics Series 420 PTO (Power Take Off) Shaft Torque and Power Monitoring System will monitor and log the torque, shaft speed and transmitted power accurately when testing new systems driven from all standard PTO Shafts.

Torque Calibration

Datum Electronics specialise in the servicing and calibration of torque transducers for their own non-contact ranges (Series 420 torque transducers) and reaction torque transducers (Series 410) plus many other commercially available torque sensors.

Torque Trails Kit

The Datum Electronics Series 430 torque trials kit is a temporary fit system designed to measure the on-shaft torque for trials applications on rotating shafts between 150mm to 1100mm in diameter.

Torque Measurement

Our Rotary torque solutions come in an array of different types and varieties. Our experience and expertise allows us to offer flexible, workable solutions that meet the needs of our customers across a number of industries. Torque measurement can be used in a number of different applications and for different requirements, including monitoring and control, power management and increased efficiency savings. If you are looking to measure/control power, torque and speed then our range of torque instrumentation has been designed to help you. Typical applications where torque measurement has been utilised can be found here.

We have a standard range of torque sensors and instrumentation which we have developed over a number of years. Measuring torque in Newton Meters (Nm) as standard, we can measure torque from as low as 5Nm up to and including 500,000Nm. We use a strain gauged shaft; that can be incorporated into most commercially available drivelines via either a keyway, spline or flange shaft. Our torque sensors use standard RS232 digital data to transmit torque, giving fast and effective data that is clean and easy to use.

Although we have a standard product range, our capabilities can extend beyond the minimum requirements; below are just some examples of options available:

Specifications Available

| Torque Rating |

5Nm up to 500,000Nm |

| Rotational Speed |

0 - 20,000rpm |

| Data Sampling Rate |

0 - 20,000 samples per second |

| Torque Output |

RS232 / RS485 / 0-10V / 4-20mA / +/-10V / +/-12mA |

| Calibration Units |

Nm / lbft / ib-in / kNm |

Shaft Options

|

Standard: Flange/Flange, Keyway Shaft, Spline shaft

Non-Standard: Can be fitted to free issue customer shaft |

| Accuracy |

System Accuracy 0.1% (0.05% options) |

| Environmental Protection |

IP54 (Standard) up to IP68 if required |

Torque Analysis

|

Standard: Torque, Speed and Power

Optional: Torque Ripple |

Contact us if you would like to find out more about how we can help you and your application. Visit our Contact page and contact us with details of your application; alternatively click on any of the links below for more information on our torque related products.